Denim Mis-information

Why does the public — and sometimes even industry insiders — seem to think jeans are so bad for the environment?

They have been called by various publications and brands, “one of the least eco-friendly clothing items to produce,” that require “an embarrassing amount of chemicals, thousands of liters of water and energy consumption that has been almost comically outsized compared to the finished product.” (And this last slur is from a denim brand!) Even Patagonia once said in its marketing that “Denim is a filthy business.”

Is it true that denim is the worst?

No, says Miguel Sanchez, Technology Leader for Kingpins and a textile engineer for the Polytechnic University of Catalonia. “Like any other fashion product, there are different ways to produce it,” he said. “If you just follow simple rules and you use your brain to do what is right, denim is not worse than any other fashion product.”

Franky Vangaever, who worked in technical innovation for Levi’s for 33 years before leaving last year to found a company in Belgium called Responsible Textile Innovation, agrees that denim isn’t particularly dirty. “It depends on the sustainability vision and goals from the brands,” he said, “as well as the suppliers they’re working with. Do they have a chemical stewardship program? Is there onsite control of what is used on their products? Using the right technologies, denim can absolutely be produced in a very sustainable way.” He adds that denim is often produced in the same mills as viscose or polyester. “We don’t have many suppliers where they are only making denim. If they are clean on the denim side, they will be clean on the other side.”

So why all this negative attention? Well, denim as an industry is easy to define and measure, and several studies have been done on the impact of a pair of jeans. No similar life cycle analyses have been done for sweaters, pants or bathing suits. The upside is that what you can measure, you can manage. “It is not a filthy business,” Sanchez said. “But we all agree that things can be done in a better way.”

So, what are some of the basic rules of making eco-friendly denim? Let’s get into them.

Cotton’s Environmental Impact

Much of denim’s supposed negative impact is pinned on cotton. For example, in Levi’s lifecycle analysis of jeans produced in 2012, 68 percent of the water for a pair of jeans is used in the cotton field. Some media have said it can take more than 20,000 liters of water to produce one kilogram of cotton. But these figures are misleading, and in the latter case, completely wrong.

There is a lot to say on this topic, but the short version is that there’s no good average cotton water statistic, as cotton’s environmental impact varies so much from country to country and even from farm to farm. But it’s important to note that half of all cotton is grown using only rainwater. And the irrigation water that is pulled from local water sources runs around 1,200 to grow a kilogram of cotton, according to the ICAC Cotton Data Book 2020. That water can be recycled and used again for other crops or in a farmer’s home, or even put into the local ecosystem.

Cotton’s use of pesticides has also been overblown — it’s the fourth largest user of agricultural chemicals — not the first as is often claimed — according to PAN UK’s 2018 Chemical Addiction report, though there is definitely a need for more support for smallholder farmers so they can reduce their use of pesticides.

But cotton, and the denim made from it, has its benefits. Not only does cotton provide for the livelihood of millions of farmers and their families, it’s a durable, yet biodegradable and recyclable fiber. Unlike synthetic fibers, it breaks in instead of down, making for a long-lasting garment that doesn’t contribute to microplastic pollution.

So the solution to cotton’s role in denim’s impact is not to find an alternative — denim isn’t denim if it isn’t cotton — but for brands to support programs that help farmers grow more sustainable cotton and to pursue supply chain transparency. FibreTrace is one technology that promises to give more clarity on the exact amount of water and chemistry used on the farm for one pair of jeans.

Denim’s Water Use and Pollution

Let’s go back to the water issue. Fashion Insiders says the entire lifecycle of jeans, including consumer use, can require up to 2,900 gallons (almost 10,100 liters) of water, two and a half times what Levi’s estimated. (Fashion Insiders does not cite a source for this number.)

“It’s not true that denim requires a lot of water,” Sanchez said. According to Levi’s analysis, a pair of 501 jeans requires 3,781 liters of water. 2,565 liters is used to grow the cotton, and 860 liters is imputed to consumer washing. That means only 9 percent of denim’s total water impact is at the denim mill, laundry or factory. Vangaever, who had an inside view of this LCA, says the water usage apportioned to manufacturing might be 5 percent higher, but that still makes manufacturing a small part of denim’s water footprint.

And yet, much of the fear mongering around denim’s impact has focused on the factory. According to Everlane, the standard washing process alone wastes about 1,500 liters of water for each pair of jeans.

Vangaever says that an old belly washer machine can waste up to 1,500 liters because they have a very high liquor ratio, which measures how much water you use for each kilogram of denim. “Those washers are very old, but popular in China, Mexico, and Bangladesh — the cheap labor countries,” he said.

But in the modern laundries, you’ll find front loaders from Tonello or Jeanologia, which can cut water use by 70 to 80 percent, according to Dr. Siva Rama Kumar Pariti, Senior Technical Marketing Officer at Sustainable Textile Solutions a division of Bluwin Limited. Coupled with resource-efficient processes and adjustments to the recipe, the whole laundry process can be taken down to 11 liters. So the average water consumption in a denim laundry for one pair of jeans is 70 liters, not 1,500.

The ironic thing is that a lot of denim’s bad reputation comes from advertising campaigns that are talking about a brand’s new, more sustainable product. Patagonia’s 2015 “filthy business” campaign was promoting jeans that it said used 84 percent less water, 30 percent less energy, and produced 25 percent less carbon dioxide. Everlane was comparing that 1,500 liters of water unfavorably to the Saitex factory’s use of .4 liters of water, after recycling. The industry secret here is that the denim mills and laundries that produce for these brands that market themselves as the most sustainable also produce for many other brands, who don’t happen to build advertising campaigns around this subject.

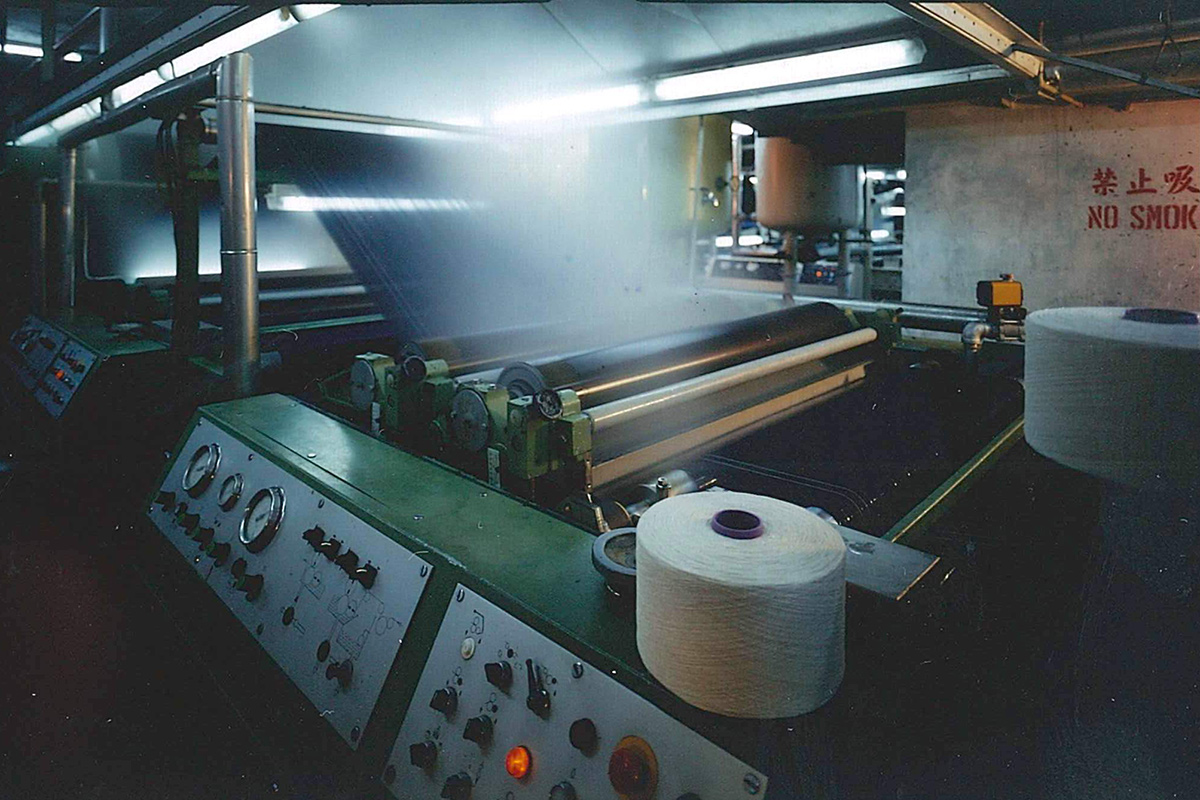

The process of creating denim is much less thirsty than it was 20 years ago. Unfortunately, reliable numbers are hard to come by in the denim industry (and the fashion industry in general). But as an example, the dye boxes, where yarns are run through six to eight times in what is called dipping, used to contain up to 3,000 liters of water and dye. “Today, you can get the same results, or even better, using smaller boxes that are at 700 liters,” Sanchez said.

Dr. Pariti puts water consumption during an indigo dyeing — including pre-treatment, feeding dye boxes, washing, sizing and mercerizing (treating the denim so it holds or releases the dye) — at five liters per pair of jeans. Newer technologies such as foam dyeing can reduce water usage.

But not all denim mills are switching to the smaller, newer dye boxes or foam dyeing techniques. They’re a large investment. Denim mills have very small margins and so far brands have proven reluctant to pay a premium for more sustainably made denim, or use their significantly larger capital to help a mill invest in more sustainable technology.

Another sore spot for the denim industry is water pollution. Many who criticize denim reference a 2013 article talking about denim laundries in Xintang, which reportedly dumped blue water untreated into local waterways. Or they reference Greenpeace’s 2010 report on the results of sampling riverbeds in Xintang. It found levels of lead and copper exceeded national “soil environmental quality standards,” while cadmium levels were 128 times over the limit and the water pH level was 11.95, which is similar to ammonia.

This kind of pollution from a denim mill is not a standard part of making jeans, and you won’t find blue rivers outside of responsible denim producers in Italy, Spain, the US, Mexico and yes, China.

“What you see in some videos on YouTube, or in the pictures of a river… this is because the dye bath was totally mishandled, was not collected, was not treated,” Sanchez said. “That was probably a mistake or an accident. But that’s the kind of thing that should not happen.”

Dr. Pariti agrees, saying the wastewater should have been treated to bring the pH level in line.

“Generally, export oriented companies are on a much higher level than domestic producers,” he said. What he’s hinting at is that the jeans you can buy in the U.S. and Europe are likely not contributing as much or at all to the pollution highlighted in Xintang.

Denim’s Dye and Chemicals

A Business Insider article claims that blue jeans contain azo dye, which can release carcinogenic molecules called amines during production and when the consumer is wearing them.

This is categorically untrue. While it wouldn’t be surprising to find azo dyes in a cheap black t-shirt, you won’t find it in a pair of jeans. Real jeans — emphasis on real — are not toxic.

Let’s explain what we mean. You can identify real denim by examining the weave, then folding it over and looking at the back. Denim is close to 100 percent cotton. Denim’s warp yarn has been dyed using the process described above with synthetic indigo (which is not an azo dye) making the front of the fabric blue, while the back of denim shows the undyed white weft cotton yarn. Black denim, which uses what is called Sulfur Black, a dye of least concern, is also safe, depending on the dye process. “It’s the opposite chemistry of AZO dyes,” said Sanchez, who has 30 years of experience in textile dyes and chemicals.

Fake denim, on the other hand, is a fabric that has been dyed to look like denim, with a blue front and white back. That can contain azo dyes. Non-denim “jeans” have fabric that is dyed solid on the front and back, and can contain a textile blend on the front and have a polyester backing. “It is often dyed with reactive dye on the front and azo dyes on the back,” Sanchez says.

Indigo dyeing is not perfect. Traditionally, giant bags of powder indigo would arrive at a factory and workers — without any protective gear — would cut them open, releasing dust bombs containing thousands parts per million of aniline, which is toxic if inhaled. Vangaever says 46 percent of indigo used today is in powder form. But there are many new sustainable technologies for indigo dyeing. There’s gassed-on foam where you impregnate your fabric with indigo, Cadira Denim by DyStar, where they spray indigo into the yarn, and smart INDIGO by Sedo Engineering in Switzerland, which uses electricity to impregnate the yarns with indigo. “That is much more sustainable than working with powder indigo,” Vangaever says. “The problem is that brands are not pushing for it. The brands don’t want to take any responsibility. They go to the supplier and say, ‘This is what I want. How you do it, I don’t care.’”

Reputable brands take an interest in how their denim is dyed and require denim mills and jeans factories to test their product for safety before shipping it. But more to the point, it’s the denim supply chain that has stepped up to take responsibility.

“Denim mills and suppliers of chemicals are extremely responsible,” Sanchez said. “I cannot [disregard the possibility] that a crazy mill somewhere in the middle of wherever is sourcing chemicals from whatever company that is known to still be doing something wrong. But this is not the way denim is going. Denim is fighting hard to have a clean face.”

Distressing and Fading Jeans

To distress and get that washed-out look for jeans, factories engage in a range of processes. And yes, some of them can be dangerous for workers, if not done properly.

Sandblasting produces a fine dust that if inhaled by workers can lead to silicosis and lung cancer. Using hypochlorite (what you may recognize as Clorox, but at three times the strength) and potassium permanganate to fade and bleach jeans can create some extremely dangerous fumes. Resins containing formaldehyde can also be a part of the process. Stonewashing, when jeans and pumice stones are put together in a large washing machine, can produce a sludge that hardens into concrete, clogging pipes and waterways if not properly handled.

Less problematic is hand-distressing jeans using sandpaper, and creating holes in the jeans using power tools. These processes can still produce dust, however, and if that dust is coated with whatever chemicals were put on the jeans, it’s not healthy for workers to breathe it in.

That’s why responsible factories provide proper protective equipment (PPE) to all employees working in washing and distressing, to protect them from inhaling this dust. One strategy is a fine waterfall that drops from the ceiling, which catches dust and fumes before they reach any workers. “In general, in many countries, proper PPEs are being worn by workers,” Dr. Pariti said. “There is still a lot of work to be done in terms of providing proper PPE and educating the workers to ensure that the given PPE is properly used and worn during the production processes.”

There are innovative and safer ways to get that distressed look, namely using robots instead of people where possible, using lasers to create holes and using enzymes to break down the fabric.

There are two things preventing all jeans suppliers from switching completely to these alternatives. One is that the new technology, such as lasers, doesn’t yield quite the same authentic look with so much depth. As long as consumers demand the ability to purchase new jeans that look authentically worn in, brands will provide them with it (and perhaps look the other way at what it takes to get that look).

The other roadblock is, again, that these technologies, especially robots, are expensive and brands so far haven’t wanted to help fund them or pay a premium for denim distressed with newer and safer technology.

“It is much cheaper to hire five people than to buy one of those laser machines,” says Vangaever. “There should be much more support from those brands to push those technologies.”

Denim’s Energy Use

According to an oft-cited paper put together by Dutch waste companies and two universities, denim uses a high amount of energy in production, both because of the spinning machines and the specific humidity and temperature required for the factory.

But spinning cotton into denim doesn’t require way more energy than spinning any other textile. According to the Higg Index, the climate impact and fossil fuel use rating of spinning and weaving cotton is about the same as wool and polyester. We’re talking a climate impact rating of 2.61 for cotton versus 2.09 for polyester and 2.38 for wool. (With a climate impact of 6 during yarn formation, linen blows them all away.)

That doesn’t mean mills shouldn’t focus on energy efficiencies and alternative energies. They absolutely should. Some are investing in solar panels for their roofs, using agricultural and commercial waste products instead of fossil fuels waste to run their boilers and finding other ways to reduce the climate impact and fossil fuel use of their factories.

Denim’s Care & Use

This is where jeans, by all rights, should shine. A core part of any person’s wardrobe which gets frequent rotation and that only gets better with time, jeans are the ultimate slow fashion product.

Unfortunately, in lifecycle analyses, the use and care of jeans is purported to use a lot of water and energy. Levi’s lifecycle analysis says 23 percent of the water use and 37 percent of the climate impact of a pair of jeans is caused by consumers washing and drying their jeans.

The Dutch report also talked about the high environmental impact of consumer use of jeans, assuming a pair would be washed 50 to 75 times in its lifetime. But what a compliment to jeans, that consumers are assumed to wear them at least 50 times before discarding them. That’s not the case for much of the mass-market fashion that consumers buy today, which may be worn a few times in a season before going out of style or falling apart.

“Denim is a high added-value product,” Sanchez said. “Unfortunately, the way that mass fashion has been handling denim is terrible, because they have basically killed the spirit of denim.” He’s talking about the fake and non-denim jeans that have conditioned consumers to treat jeans as fairly disposable products, instead of building a long-term relationship with them.

So, How Does Denim Affect the Environment?

As you can see, the climate, water and health impact of denim can vary widely. (Transformers Foundation, a non-profit that specializes in the jean industry, is working on a process to measure a jean’s impact more precisely.) Whether a pair of jeans can be considered more sustainable depends on where the cotton is sourced from, whether it’s authentic denim or a fast-fashion poser and how the end consumer chooses to clean and take care of their jeans.

But above all, it depends on whether they were made by reputable suppliers who have invested in efficient and safe technology. And there are plenty of those in the denim industry.

“Denim is an extremely innovative fashion segment,” Sanchez said. “We use technologies that are not yet even remotely considered by other types of apparel segments. We use lasers. We use robots.”

“This industry is rapidly upgrading,” Dr. Pariti agreed. “They are becoming more responsible day by day and they are more responsible than the suppliers in other fashion segments.”

We here at Kingpins have high standards for the denim industry as well. If a mill or factory says that they are saving water and energy, we like to see proof. And so far, the industry has demonstrated it takes this topic seriously.

“Denim people, in general, are very responsible,” Sanchez said. “They want to really show proof that they are performing well.”

So the ball is your court, brands. The technology is there. The willpower from suppliers is there. The demand from consumers is there. All the industry needs is your support and investment, and a pair of jeans could be guaranteed the most sustainable item in a consumer’s wardrobe.