Kingpins Stories – Rowan Hunt: Lessons from the Denim Journey

At the beginning of my career — about 18 years ago —I was lucky enough to land a job as an assistant designer at Dewhirst, a longstanding, well-respected and large supplier to M&S (Marks & Spencer). The U.K. team was big with support for each function. In addition to sales and merchandising teams, we also had an incredible and knowledgeable team of fabric and garment technologists. I couldn’t have asked for a better start to my journey with these gurus who could answer nearly any question I threw at them. And I threw a lot!

My never-ending curiosity may have annoyed them at times, but I know they knew that I just wanted to learn and be better at my job.

Fast forward nine months, and I had my own department with sales targets in outerwear. I was off to the wider world, straight into countries like Indonesia, China and Hong Kong, later adding Vietnam and Bangladesh into the mix.

This is truly where you see the wider issues and really see how things are made and done. My mind was blown, and with that, more questions came.

Every time you learn something you level up and generate two more questions. You practice what you know to perfect the skills.

LESSON LEARNED: Never be afraid to ask questions. We are all here to learn from each other. Not asking is worse.

I had learned about fabric construction “counts,” spinning, finishing and many more things at this point.

I could now rock up to a mill meeting and reel off fabric constructions and counts of key fabrics that we were looking for. We could then look for ways to cleverly reduce the price or slightly change the look of the fabric. For example, if it was a 32 thread count with a construction of 150×100 ends and picks, then going with a coarser thread and reducing the ends and pick can give something a bit different. This was great learning but also so much fun. I enjoyed not only thinking outside the box, but also applying logic so that the end result wasn’t too crazy or out there.

I really loved this part of research. While on a shop report, I would try to guess fabric construction and qualities and then discuss with both the senior and the junior technologists when I got back. We would cut a bought garment, weigh it and try to make educated guesses on what it might be.

At this time, I focused mainly on fabrics, occasionally dealing with the odd jacket with an enzyme wash. And in my design packs I would just specify “enzyme wash.” An enzyme wash is just an enzyme wash right? Oh, I had so much to learn!

I looked into processes like acid washing. I would ask for an acid wash in Indonesia and they would look at me blankly. To them it was a “bleach wash” or “crazy wash.” When I asked what chemicals they used, they said they used KMnO4. Wait one minute, I knew this by another name: PP wash. To them it was called “snow wash.” I later learned this is also called “moon wash” in other parts of the world.

LESSON LEARNED: Many people around the world use different processes — or sometimes just different terminologies — to get the same look.

After this came an interest in garment dyeing and getting to know pigments and reactive dyes, then direct dyes and on it went.

For one brand I worked with, we designed a pigment garment-dyed polo range with one of our suppliers. They were really cool, casual garments, constructed with bulky parts to reduce the amount of dye take up on places like the bottom of the placket.

For our first meeting, the showroom was a rainbow of color with all these lovely garment dyed polos. Then I noticed a few in solid navy and black at the back. Puzzled, I asked the supplier “’the range is fully pigment garment dye, right?” His reply: “Yes.”

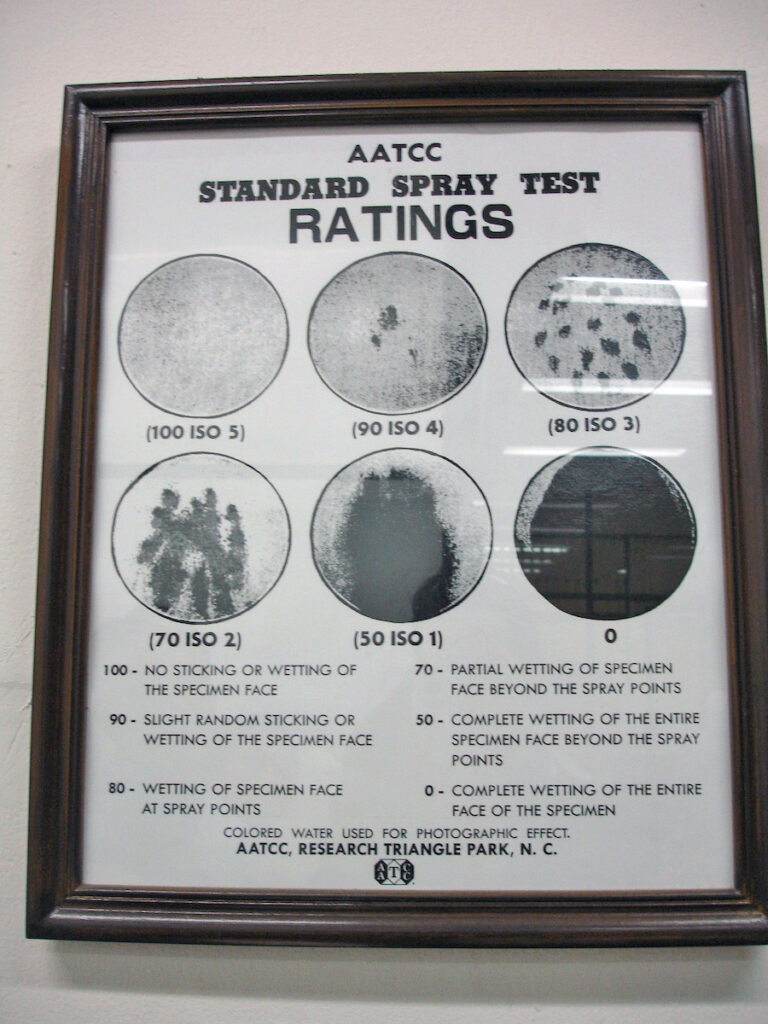

At this point – thankfully – I knew enough to know that pigment dye washes down and reactive dyes are solid. So I told them I didn’t think that these solid polos were pigment dyed. They went off to check and sure enough, the three solids were not pigment dyed. They had changed these colors to reactive dye when they didn’t pass the wash standards set by the technical team.

This experience made me engage more with my team to understand how and why they set those standards and to help figure out a solution. Do we accept lower results on a wash test or can we dye differently? Could we use a light reactive base with pigment on top, perhaps?

LESSON LEARNED: Trust your experience. Don’t just blindly follow.

This particular job is where my bestie, Salli Deighton, and I crossed paths for the first time. It turned out that we were from the same geeky technical world. She came on board to help with denim and I did the rest of the men’s range. It was great to have someone to learn from and bounce ideas off.

Fast forward five years and we were both working together in Debenhams department store in the U.K. heading up development and sustainable development. We visited amazing companies like Tonello, Jeanologia and Near Chimica to learn and develop collections using the best kit. Then we’d replicate it in the Far East.

We came back from development trips and shared the future vision with the senior board. We even had “machine of the week.” Each week we would learn about a specific machine, learn what it could do, its loading size, any special parts, etc. It pushed all of us to learn and grow together. Then we would have an end of the week quiz — and a little prosecco!

This was a truly exciting time that was borne out of all the amazing research we were lucky to do.

We could see the future of sustainability in our industry. It was clear to us that there are better ways to do things and it was also clear that we needed to tell and share this knowledge with others. It can’t be done alone. We all need to work together..

LESSON LEARNED: Wise advice from one of my mentors: Take the team on the journey with you

Unfortunately, this exciting and inspiring time did not last. The company’s denim sales were steady but sales declined in other departments. To fill the hole, the budget was cut for these research trips, internal sourcing teams were cut and the company began using more third-party suppliers. Morale was affected, people left the company and those who remained were left with more work and less opportunity to use all the futuristic innovations we had researched. This is the ying and yang of our jobs as creatives.

LESSON LEARNED: Take away the inspiration and creation slows.

I was approached about an account rep job for both a fabric mill and a garment vendor. I didn’t think I wanted to be in sales but, on the other hand, what better way to learn more about fabrics, dyeing, weaving, fibers and even washing garments to show off the fabrics? Learning at a garment unit had a similar appeal. I could learn, research and apply researched ideas too. The buzz was back!

It was great to have chances to apply the things I had researched when I came across companies like FibreTrace. I even met with the inventor and learned about the origins. The logical next step was to connect the dots and use FibreTrace with a fiber producer then make it into fabric with my mill. When presenting this to buyers, it didn’t feel like I was pushing sales. I was enjoying sharing this amazing idea and product — as well as my knowledge of it — to whoever wanted to learn.

I had similar experiences with the garment vendor. When I was in Cambodia developing washes, I spent my free time experimenting with machines like a G2 ozone from Jeanologia. What wash effects can we do? How does it differ when wet or dry? What is the optimum wetness to discharge color? After talking to people about the research I was doing, I got Jeanologia’s Brainbox and technical teams out to a factory at the same time.

That’s when I learned about Jeanologia’s EIM diploma and started asking each factory I worked with to train at least two people to input EIM information and receive EIM diplomas. I would check the scores to make sure it was correct and honest, which made me realized that if I was asking the factories to train their teams correctly in EIM then I should probably do so myself. So I did. I took the course and I got my diploma.

LESSON LEARNED: No matter what your job is, research and learning is the key to an exciting and fulfilling life.

What’s next? What do I need to know? What research avenues do I need to go down or require?

In addition to my overseas travels, I also look to research locally.

For example, what’s the best way to learn whether a pair of jeans will actually biodegrade? Plant the jean in your garden and document it. So, that’s what I did. When I talked about my experiment with my friend, Miguel Sanchez, he suggested I dig up the jeans every four weeks or so to check the progress. Great idea! Add in variables like temperature fluctuations and rainfall and I have the beginnings of an interesting independent study.

When I wanted to learn about natural dyeing with nature, I found a local dyeing course, which provided a lot of ideas for further research.

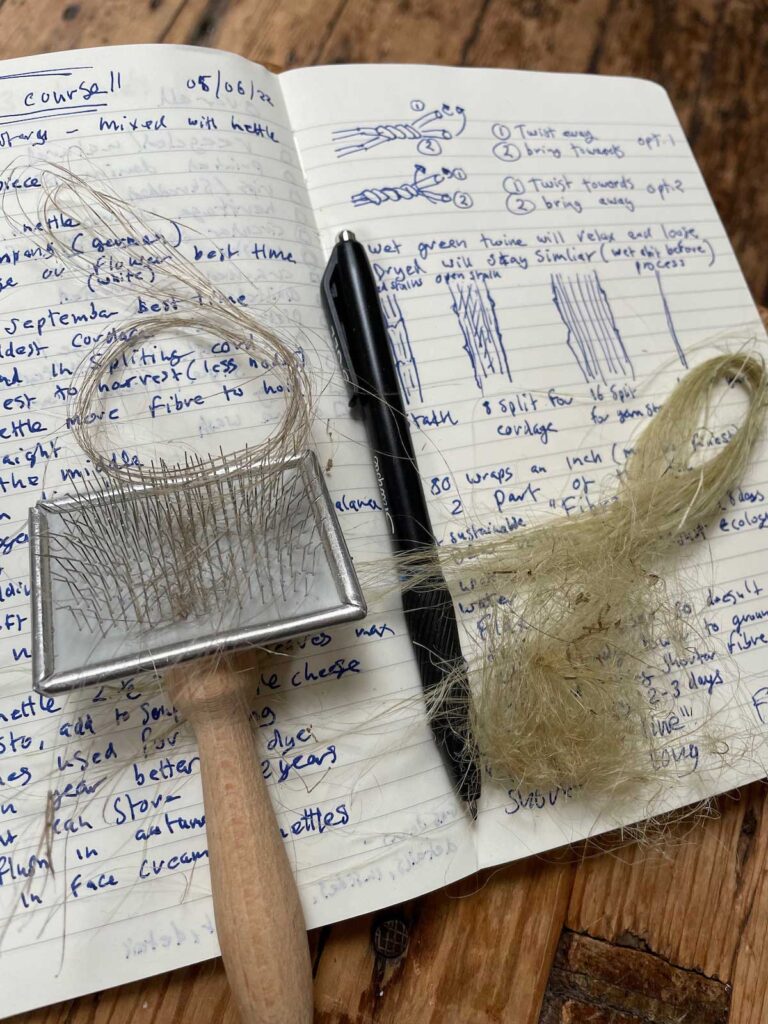

Same story with “forgotten fibers” like nettles. It’s a bast fiber that grows everywhere in the U.K. — and they are free. I spent nearly three years researching and doing trials with nettles that I found growing on the side of paths and roads in our local village. Then I found a local course and studied the whole process from plant to harvesting, striping, combing and spinning. Again more research!

What I needed was a small lab or R&D facility on my doorstep, which brings us to LaundRE, Salli’s “laundry of the future” project (Read Salli’s Kingpins Story here). It doesn’t need to have robots to be called futuristic, but it does have to provide solutions to our current problems and the problems of the future.

Waste, overproduction, post-purchase laundering, these are some of the issues our industry needs to research.

The spelling is intentional to draw attention to the big “RE” we need: Recycle, repurpose, rethink, reimagine, re-educate — and, of course, research!

The stage is now set for the next chapter of research and development. And overarching all of that is the need to educate the buyers and designers and consumers of the future. That is the mission of this laundry of the future and, I believe, it is the path forward to create the denim industry of the future.

Find Rowan Hunt on LinkedIn: Garment wash & process consultant

Rowan is a founding member and CTO (chief technical officer) of LaundRE and is also the founder of Denim Research: https://www.denimresearch.com/